How loud is too loud?

The environments in which today’s electrical machines operate pose new acoustic challenges. Electric vehicle designers, in particular, are being pushed to reduce noise levels to meet acoustic noise limits and requirements.

In the past, experimental electric motors were developed early in the design process to be able to assess their noise performance before full-scale production. Unfortunately this approach created an unpleasant experience for motor designers. The mitigation solutions often required substantial modifications to the expensive prototype models, opening the door to the nightmare of forcing engineering changes to an existing machine. For this reason, the use of computer software in noise and vibrations analysis has attracted a lot of attention in recent years.

Noise: a multiphysics simulation problem

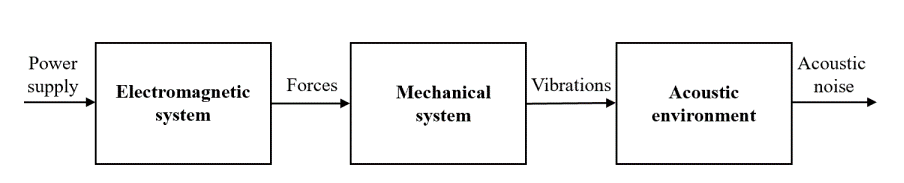

In the digital environment, acoustic noise is formulated as a multiphysics simulation problem consisting of three coupled sub-systems:

- An electromagnetic subsystem to calculate the exciting forces

- A structural subsystem to estimate the vibrations at the stator surface

- An acoustic subsystem to translate the vibrations at the stator surface into acoustic signals

This is what we perceive as the noise.

Fig. 1 shows how the electrical energy is converted into acoustic energy in a typical electrical machine.

Figure 1. Conversion of electrical energy into acoustic energy in electrical machines.

Exploring acoustic design

Watch our presentation from the Motor & Drive Systems Conference. We demonstrated the use of computer-aided predictive software such as Simcenter MAGNET, Simcenter Motorsolve and Simcenter 3D to set the background for the computational discussion and exploration of the acoustic design space of the electrical machine.

Watch the presentation

Ready to take a new approach to acoustic analysis? Contact a Maya HTT expert today.