Industrial AI

operations

Machine learning (ML) can help to reduce material waste, increase the quality of manufactured products, ensure regulatory compliance and reduce risks.

Discover the true cause-and-effect pathways through physics-backed insight into data from industrial processes, manufacturing operations, and heavy machinery fleet operations for improved AI operations.

Topic of interest

AI readiness assessment

Model development

Model deployment & ML ops

Model interpretability or explainability

Model metrics & scoring

Framework expertise

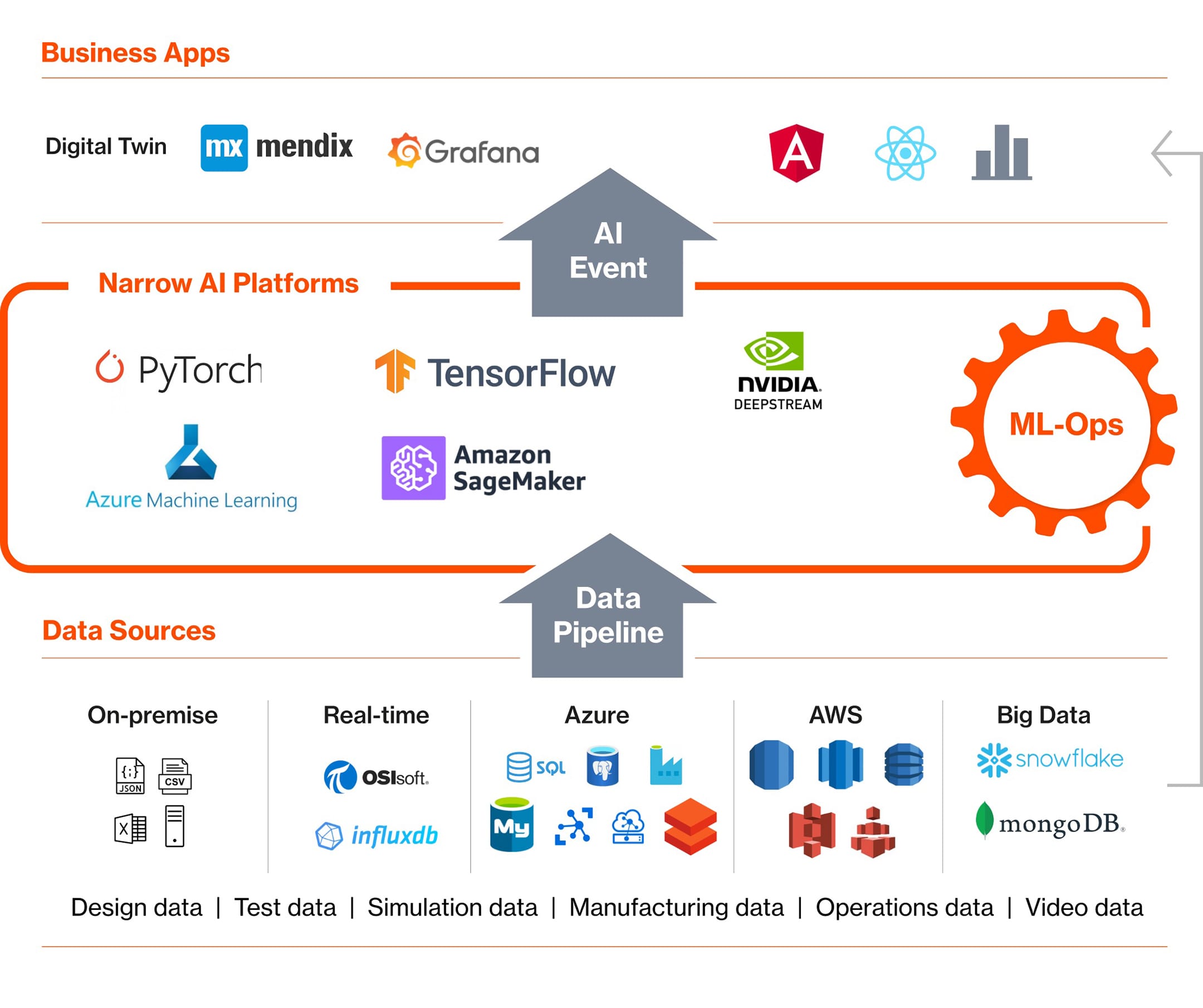

Azure ML

Pytorch

Tensorflow

AWS SageMaker

NVIDIA DeepStream

Prioritize your business use

case and put your data to work

Effective implementation of industrial ML Ops depends on deep knowledge of the physics behind the manufacturing processes. Are your narrow AI models well engineered?

Turn to Maya HTT for our hands-on expertise with

real-time telemetry and video feed processing for industrial data integration.

The artificial intelligence (AI) revolution has been underway since about 2016. As a result of great increases in computational power, AI no longer resides in the realm of media hype and science fiction. Today, AI offers concrete benefits in all areas of engineering, manufacturing, and operations. From deep neural networks and long short-term memory (LSTM) algorithms to reinforcement and physics informed neural networks (PINN), the possibilities are endless. Industry data holds gold nuggets; AI is they key to finding and using them.

As companies seek to take advantage of AI, one of the first challenges is how and where to start. By some accounts, as many as 85% of AI projects fail. Many more companies run into problems with their data. Data quantity is important, but so is quality. Having an AI goal is not enough to succeed. Strategy and preparation are key.

Simulation

Simulation