Sometimes, a factory acceptance test reveals that a piece of equipment does not perform as intended. This situation may have many causes, such as incorrectly specified components or system designs or underperforming control algorithms. Virtual commissioning makes it possible to discover those problems well in advance of the factory acceptance test.

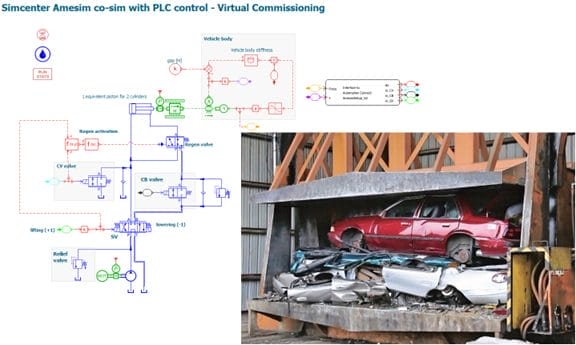

In this blog post, we present a typical approach to product development with model-based systems engineering (MBSE). The objective is to develop the hydraulic system and corresponding programmable logic controller (PLC) control software for a “pancake” car crusher (a compactor), the type used to flatten scrap cars lowering a huge hydraulically powered plate. The hydraulic system is developed in Simcenter Amesim and PLC software in the Siemens Totally Integrated Automation (TIA) Portal. Controls validation is carried out by means of software-in-the-loop, where Simcenter Amesim and the TIA Portal are running in a co-simulation.

System simulation

Simcenter Amesim offers a dedicated off-the-shelf library for a given physical domain of interest, which is very useful in reducing the amount of physics modelling needed to begin the design process. In the case of hydraulics system modelling, this is accomplished using the Hydraulic library (Fig. 1).

Fig. 1 Content of Hydraulic Library

Design considerations

When it comes to car crushing performance, two factors are important: speed and force. A faster crusher achieves more cycles per minute and greater force crushes more cars per cycle.

Although the hydraulic system for such a device is not overly complex, design decisions still need to be made. Engineers need to understand trade-offs between various actuator strokes, their rod and piston diameters, pump sizes and valves characteristics.

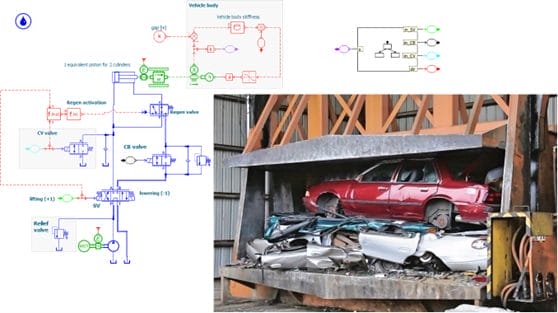

Building an actual system is not a cost-effective way to explore various system designs and investigate their performance. This is when simulation comes in handy. A Simcenter Amesim model of a car crusher is presented in the picture below (Fig. 2).

Fig. 2 Simcenter Amesim model for a car crusher (compactor) with a statechart

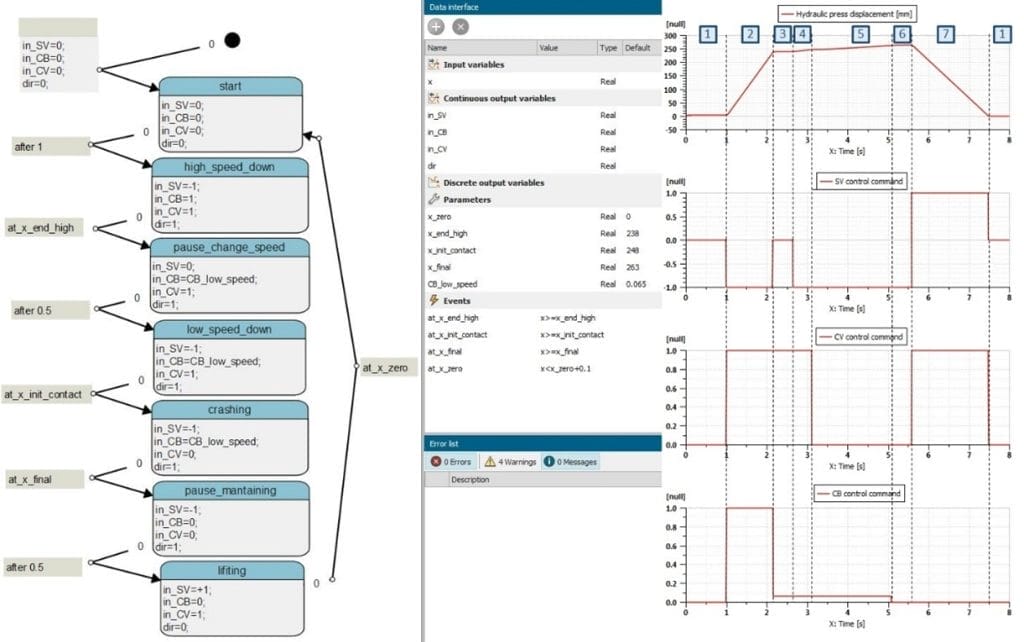

In this model, the crusher control is realized with a statechart (Fig. 3).

The statechart functionality is fully integrated within Simcenter Amesim, offering a graphic definition, simulation, and analysis for control and operating logic. Based on the Harel Finite State Machine theory, it uses clear and robust language semantics.

Fig. 3 Statechart controlling crusher operations.

The press control is composed of seven steps:

- Start of the process

- The press goes down at high speed

- A stop to change speed mode

- The press lowers down at low speed

- Compressing car(s)

- Stop to hold position

- The press is lifted back to its starting position

Improving car crusher’s performance

One way to accelerate the car crusher’s operation is to implement a hydraulic regeneration circuit. Briefly explained, the hydraulic regeneration during cylinder extension recirculates oil coming out of the actuator to its inlet, combining with the incoming flow from the pump. With Simcenter Amesim, it is easy to investigate the impact of the hydraulic regeneration circuit on press performance.

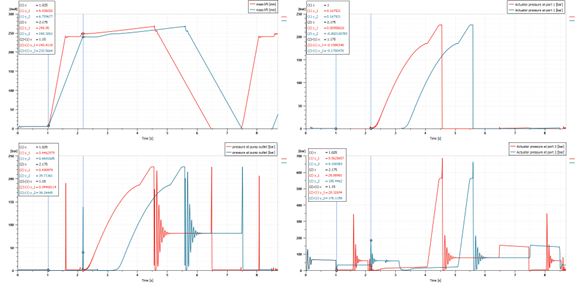

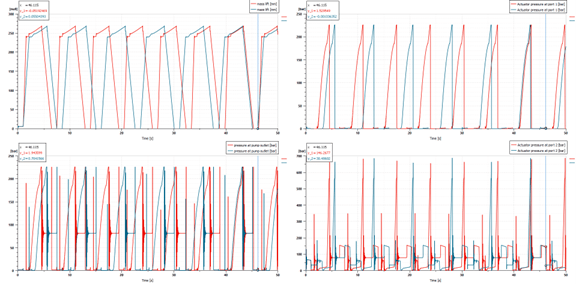

Fig. 4 System performance comparison with (red lines) and without (blue lines) hydraulic regeneration (1 cycle).

Simulation results in figure 4 show press operation over one cycle with hydraulic regeneration active (red lines) and deactivated (blue lines). It is clearly visible that the press-lowering phase is shorter when the hydraulic regeneration is activate. All other phases are not affected by the hydraulic regeneration, so the press force is equal in both cases.

Figure 5 demonstrates 50 seconds of press operation. Here, it is easy to see that the number of cycles performed within 46 seconds for the system without and with hydraulic regeneration is 6 and 7, respectively. Therefore, productivity is increased by almost 17%.

Fig. 5 System performance comparison with (red lines) and without (blue lines) hydraulic regeneration (50 seconds of operation).

Simcenter Amesim and TIA Portal co-simulations (software-in-the-loop)

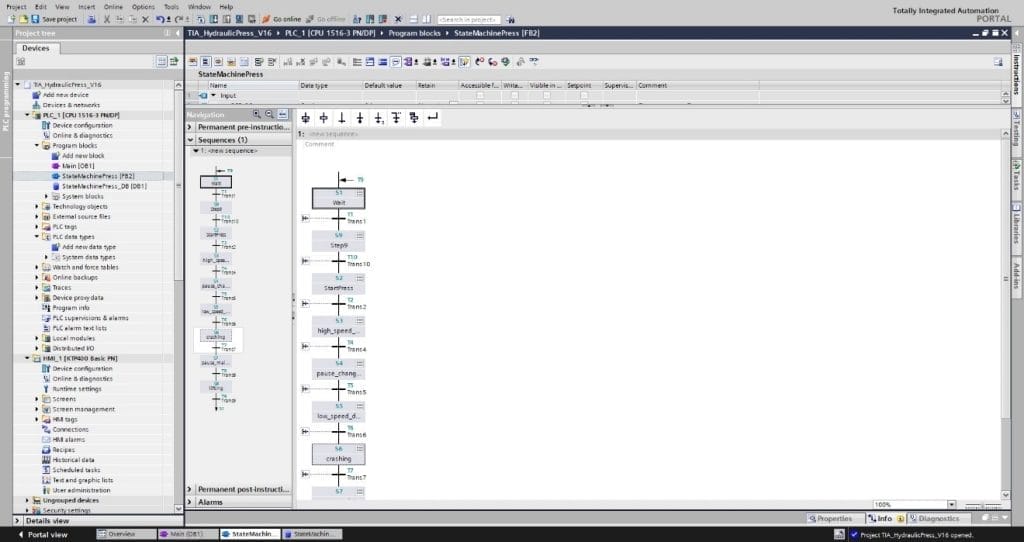

Industrial machinery is typically controlled by PLC-type controllers. The TIA Portal is designed for configuring, programming, and commissioning automation systems quickly and efficiently. Figure 6 shows a sequential function chart (S7-graph language) for controlling the press operations, and it is equivalent to the statechart in figure 3.

Fig. 6 Car crusher’s control logic in TIA Portal.

Figure 7 shows a Simcenter Amesim model in which the statechart block is replaced with an automation connect interface. This interface is a gateway for the Simcenter Amesim model to exchange signals with a virtual Siemens SIMATIC S7 controller, emulated with PLCSIM Advanced. This process is called software-in-the-loop, and it offers a way to validate the controls on a desktop PC using the real PLC program.

Fig. 7 Simcenter Amesim model for a car crusher (compactor) with an Automation Connect interface.

A “first-time right” PLC commissioned with a digital twin

Simcenter Amesim enables PLC virtual commissioning with a digital twin, and is used for system design and its performance analysis. Models created with Simcenter Amesim can be executed in real time and deployed for software and hardware-in-the-loop testing.

Key benefits of this process are:

- Virtual validation of control strategies, without putting lives or machinery at risk but using the real PLC code

- Cost reductions thanks to being able to troubleshoot errors earlier in the design process (i.e., before the real automation systems are in place)

- The creation of virtual operator training systems to familiarize operators with the controlled systems before these systems even exist

- “Virtual time” capabilities (i.e., slowing down or accelerating the time, which can help troubleshoot failures, or simulating real processes within minutes or seconds that would otherwise take hours to complete)

Curious about bringing these benefits into your product development processes?

Make first-time right solutions a reality in your operations.