Three inspiring client stories about simulation in Engineer Innovation

Our clients do amazing things with simulation software! And whenever we can, we like to share their projects and achievements with Engineer Innovation, a Simcenter publication from Siemens Digital Industries Software.

Issue 11 of Engineer Innovation should give engineers exciting food for thought. Simulation is helping to take the sustainable production, storage and convenience of food in interesting directions, from optimizing controlled environment HVAC systems to building luxury cold storage and delivering helpful robots.

Have an appetite for food that helps make the world a better place? You won’t want to miss these three articles about growing food, storing food, and delivering food with the help of simulation software.

Harvesting insights into optimized climate control designs

Harvesting insights into optimized climate control designs

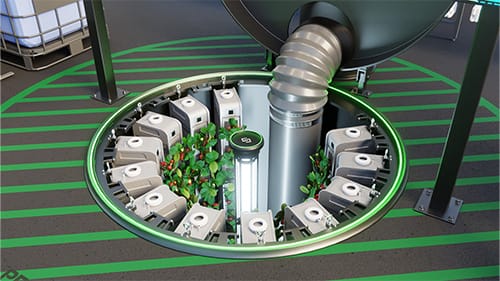

GreenForges used CFD simulation in iterating and optimizing the design of their underground controlled environment models and climate control systems. GreenForges sought Maya HTT’s simulation expertise to create virtual thermal-flow prototypes in Simcenter 3D. They were able to estimate energy efficiency and water usage to predict the cooling load. They were also able to predict the amount of condensation on the walls and the relative humidity distributed throughout one of their vertical underground forges.

Read about simulation-accelerated development

Read the interview with GreenForges

Efficient design exploration for elegant refrigeration

Sub-Zero transforms utilitarian cold storage into top-of-the-line energy-efficient performance and elegant aesthetics. The Sub-Zero team uses simulation in designing compartment microclimates within the refrigerator so that every item in the fridge can be stored under optimal conditions. With Simcenter Amesim Sub-Zero was able to explore designs and test out various scenarios faster, and the extensively customized closed refrigerant loop library Maya HTT developed for Sub-Zero helped maximize efficiency.

Read about how simulations improve closed-loop systems

Developing autonomous robot hardware and software in sync

Earth Robotics pushed past “last-mile delivery” to improve delivery through the last 300 meters. Their fully autonomous robot, Lu, makes decisions on its own and uses 360 degree vision to navigate the building, taking packages from the lobby to the occupant’s front door. That’s a fresh approach to food delivery! As a startup, Earth Robotics benefitted from special startup packaging and pricing.

Harvesting insights into optimized climate control designs

Harvesting insights into optimized climate control designs