MindSphere.

An industrial internet of things (IoT) as a service solution, MindSphere enables access to secure, cloud-based solutions and apps according to business needs.

End-to-End Integration, from Edge to Cloud

Better informed decision making is right around the corner. Store operational data of any kind and access it through digital applications, allowing industrial users access to valuable information.

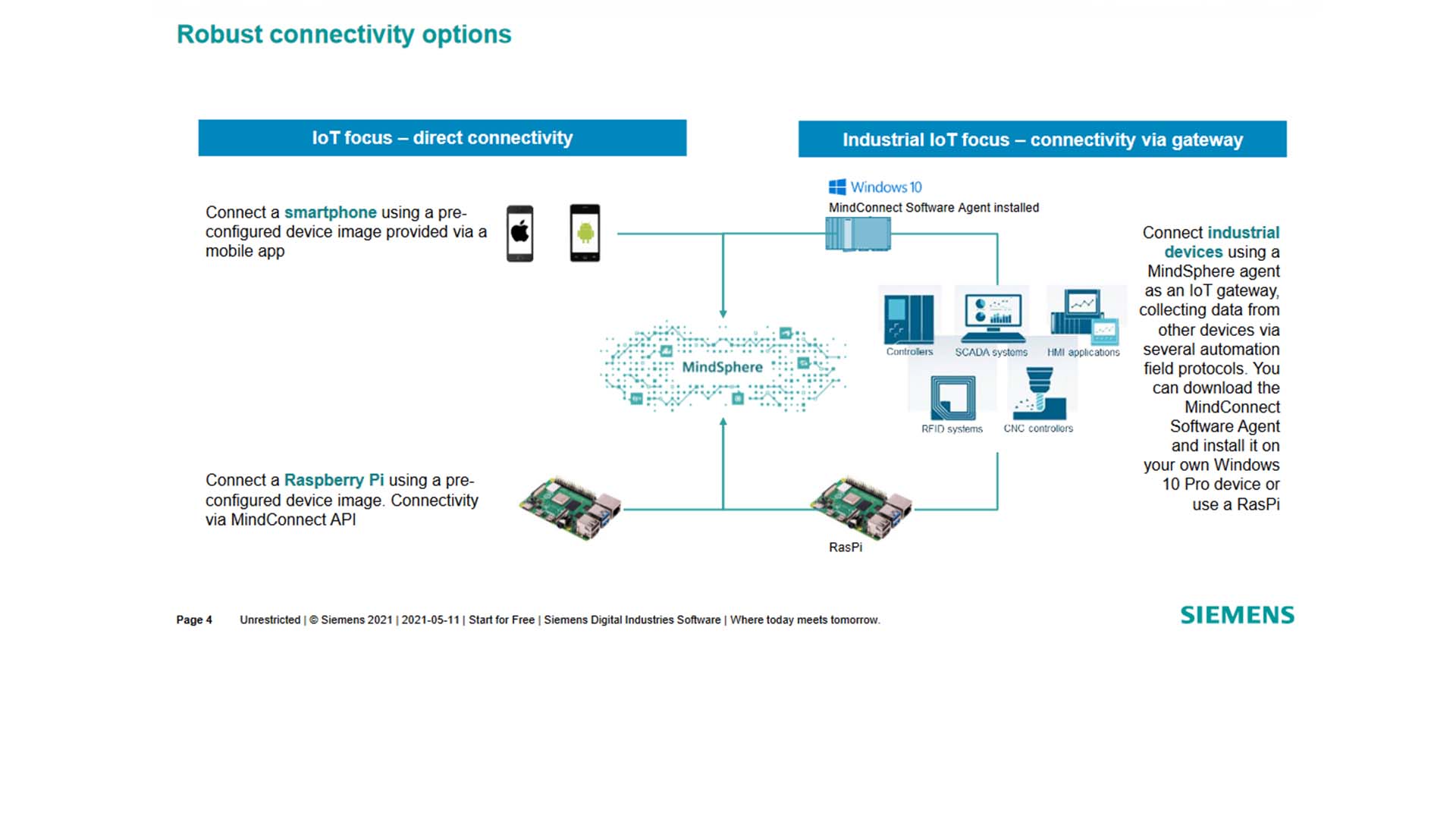

Connectivity is the key to this integration. MindSphere industrial IoT enables you to easily connect:

- Products

- Machines

- Systems

- Production plants

- Enterprise applications

Make the Most of Industrial IoT

MindSphere lets you quickly realize the business value of moving to a fully connected digital environment. By connecting your assets to the cloud, you can start exploring data, discover insights, and transform your products and processes in terms of cost and quality.

Realize benefits such as:

- Easy access to secure, scalable industrial solutions

- Comprehensive closed-loop digital twins that provide real-time performance data

- Use of analytics on edge device data and cloud data

- Ability to contextualize industrial IoT and other data using advanced analytics

Better Management of Connected Assets

Connectivity yields benefits for analysis and monitoring. Get capabilities including:

- Automatically monitor conditions and detect

unexpected behaviors - Keep track of alarms

- Set up root cause analysis and data mashups using

historical data - Correlate any asset failures with underlying data by combining events and performance data

- Compare and benchmark data from different assets across time ranges

- Visualize and track the status of assets

Easily Manage Industrial Control Systems

By running MindSphere on a Windows device or Raspberry Pi, you can connect and manage any number and type of industrial controllers and monitoring devices, including:

- Computerized numerical control (CNC) machine controls

- Systems that employ supervisory control and data acquisition (SCADA) architecture

- Human machine interface (HMI) devices

- Radio-frequency identification (RFID) tags and reading devices

When Privacy Matters Most

Some businesses have been kept from the cloud due to government secrecy regulations, strict privacy controls, or other requirements. This doesn’t mean the benefits of industrial IoT must remain out of reach, however.

With MindSphere Private Cloud, you can keep your data behind your firewall and/or utilize your own IT infrastructure. Meet any in-country or local requirements or comply with industry data protection protocols while realizing the benefits of connected control and advanced data analytics. You can also customize MindSphere to meet the specific needs of your business.

Success stories

AI in the OR: Maya HTT helps Omnimed modernize hospital surgical suites with SmartOR

One goal many of our clients have in common is to innovate products and services for the benefit...

Siemens

Self-learning application for determining the optimal settings of an industrial machine in a...

Siemens Mobility

Making operations in train stations more efficient and transparent Railway operators face the...

Contact us.

Subscribe to our newsletter

Simulation

Simulation