Simcenter 3D for Thermal

Efficiently model nonlinear and transient heat transfer phenomena, accounting for conduction, convection, radiation, and phase change. Cut the need for physical prototypes thanks to comprehensive and easy-to-use thermal modeling capabilities, such as rapid thermal connection methods, an extensive physical model library, and a wide array of thermal loads and boundary conditions.

Simcenter 3D for Space Systems Thermal

This thermal solution for space systems packs in years of industry experience gleaned from close relationships with customers and reflecting industry best practices.

Simcenter 3D for Fluid Dynamics

Model fluid dynamics with a proven 3D Navier-Stokes finite volume based solver. Accurately model flow thanks to advanced turbulence modeling capabilities and diverse validated physical models. The solver is parallelized to take advantage of available computational power.

Simcenter 3D for Durability

Available as an integrated application, Simcenter 3D Specialist Durability enables you to perform fatigue analyses and life calculations to validate structural integrity across a product’s expected lifespan under various loading conditions.

Simcenter 3D for Composites

Create, optimize, and validate composite structures – Simcenter 3D Laminate Composites streamlines pre- and post-processing of composite models. Unique features such as ply draping algorithms and automated inflation to 3D solid laminate models help to deliver the most representative simulations. The solution also lets you analyze the behavior of layered composites to ensure safe and durable structures and minimize risks.

Simcenter 3D for Acoustics

Quickly gain insight into a design’s acoustic performance with Simcenter 3D. The software provides a comprehensive solution for minimizing noise and optimizing the sound quality of products. Simcenter 3D includes dedicated acoustic modeling capabilities, efficient solvers, and visualization tools that are easy to interpret. Applications include uncoupled acoustics, coupled vibro-acoustics, and aero-acoustics.

Simcenter 3D for Structures

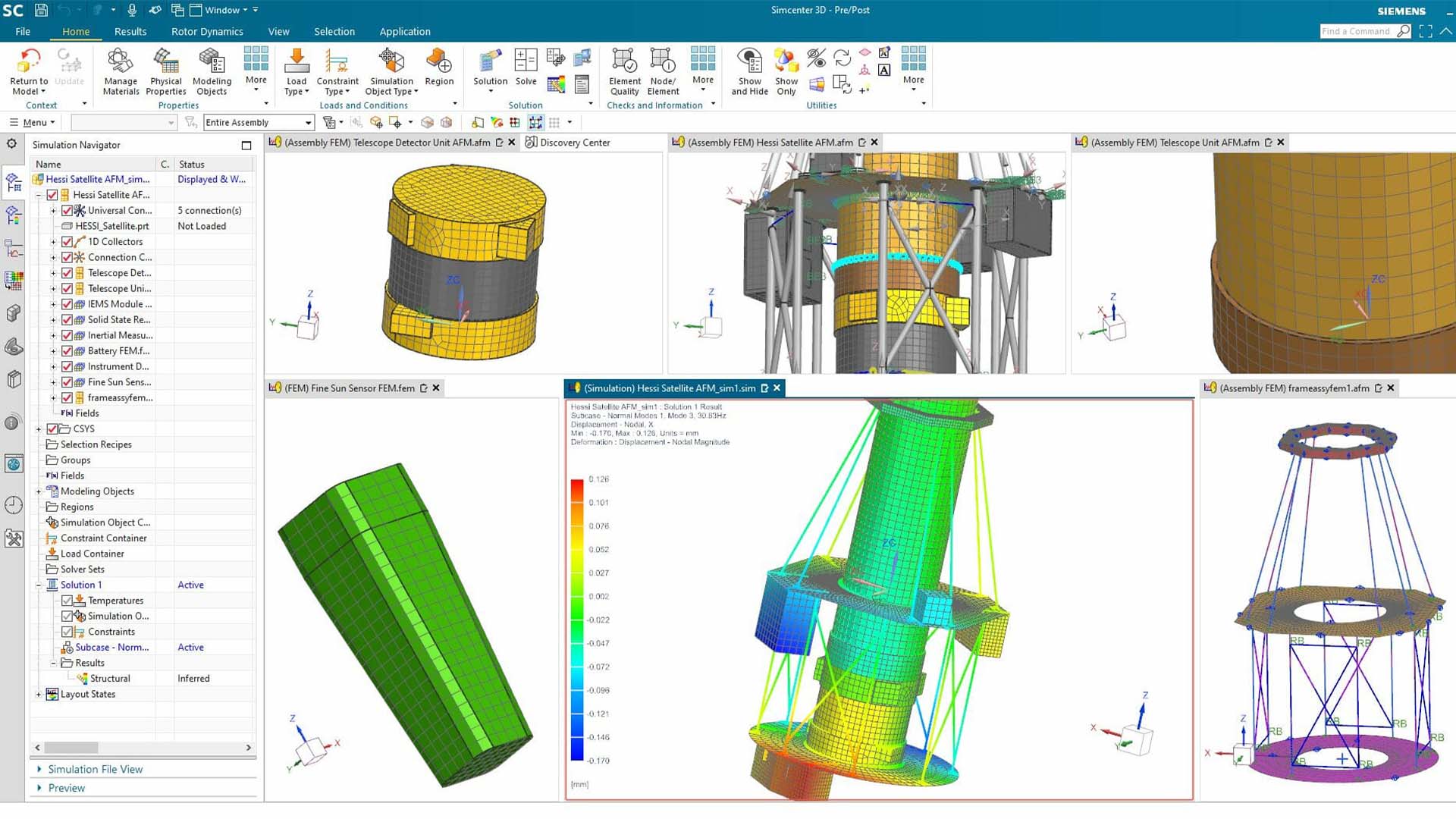

Simcenter 3D Structures bundles Simcenter 3D Engineering Desktop and Simcenter Nastran to provide a complete solution for structural analysis. Leverage CAD associativity, unique assembly and connection modeling capabilities, and automation to enable simulation-driven design.

Simcenter 3D Structural Dynamics

The structural dynamics solution covers a wide range of industries including aerospace, electronics, automotive, and marine. It offers hybrid modeling, replacing parts of assemblies with FRF or mode sets that may be simulation- or test-based, as well as noise, vibration, and harshness (NVH) response assessment.

Simcenter 3D Correlation and Model Update

Get efficient, intuitive, and productive correlation and update functions for finite element (FE) models. Run quantitative and qualitative comparisons of test results and simulations with Simcenter 3D Correlation and Model Update. This FE model updating software is fully integrated with Simcenter 3D and provides an advanced correlation tool that automatically updates FE models to correspond to real-life test data or other results.

Simcenter 3D for Aerostructures

Simcenter 3D software for aerostructures performs end-to-end assessments of aerostructures, helping to lower the costs of structural analysis and meet tight deadlines. It provides ready-to-use failure prediction methods and lets you customize the solution by securely integrating your own internal tools and intellectual property.

Simcenter 3D for Multiphysics

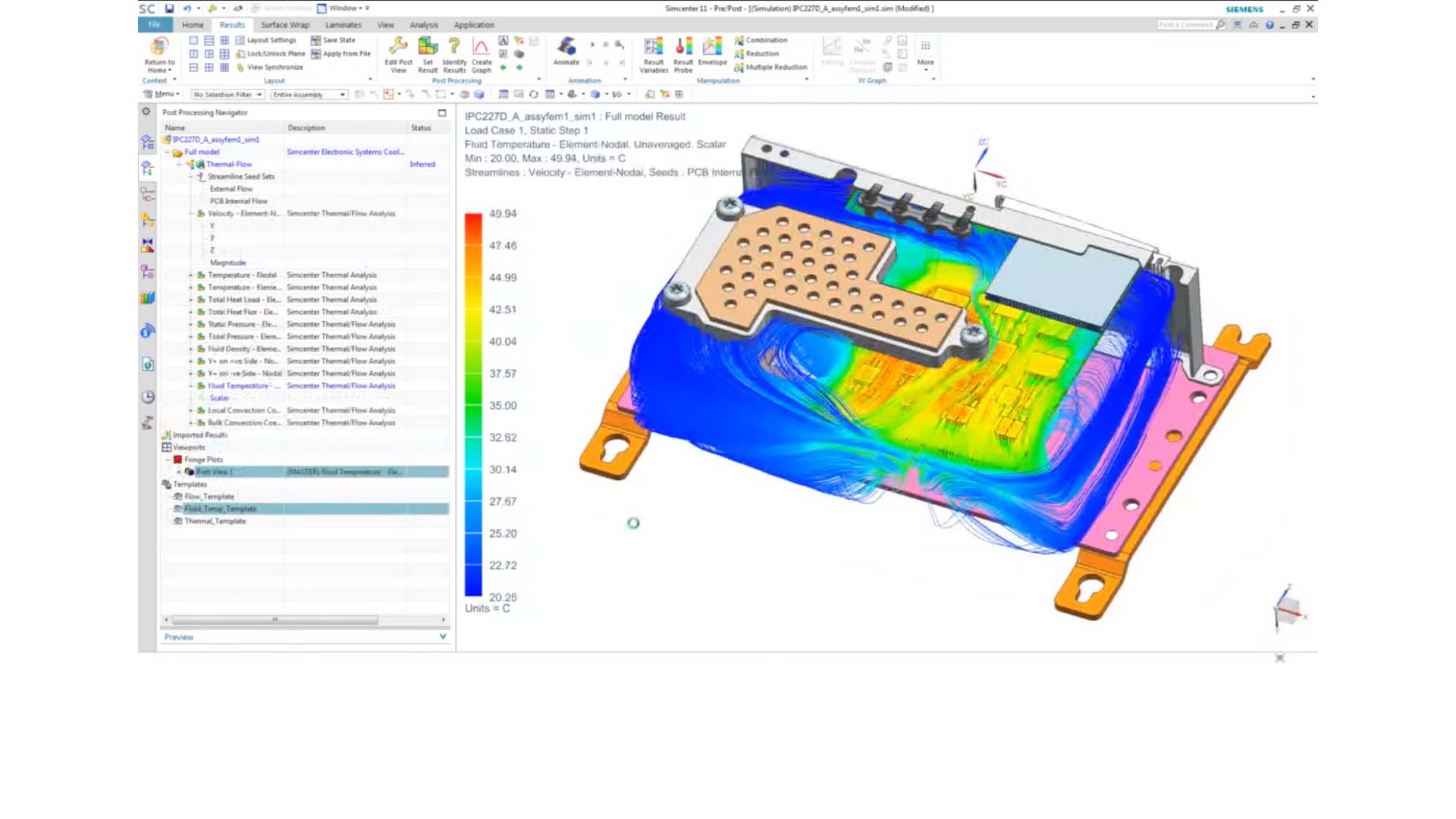

Get a single, integrated platform for multiphysics simulation with pre- and postprocessing for multiple disciplines. It includes thermal-fluid, thermo-mechanical, vibro-acoustics and aero-vibro-acoustics, electromagnetic-thermal, fluid-structure interaction, and electromagnetic-vibro-acoustics.

Simcenter 3D for Optimization

Apply topology optimization and classical parametric optimization and compare the predicted performance of a design to the specifications you require. Simcenter 3D also speeds your product design by automating repetitive iterative processes.

Simcenter 3D for Electromagnetics

Simcenter 3D for electromagnetics is designed for modeling both low-frequency EM applications such as electric motors and generators, transformers, actuators, sensors, and wireless power supplies using a variety of solvers, as well as for modeling high-frequency EM such as for communications and antenna design using full-wave and asymptotic solvers.

Simcenter 3D for Additive Manufacturing

Additive manufacturing capabilities in Simcenter 3D help you print right the first time by predicting potential distortions and defects before printing, reducing the need for test prints and boosting quality. Simulate build processes for metal powder bed fusion and explore different build positions and support scenarios.

Simcenter 3D for Motion

Easily convert CAD assemblies into multi-body dynamics models to understand and predict the functional behavior of mechanisms. Applications include transmissions and gears, controls co-simulation, tires, and flexible hoses and harnesses.

Simcenter 3D in a Managed Environment

Find data quickly, get end-to-end traceability, and connect seamlessly with Teamcenter’s entire data management portfolio, including its simulation process management module. Use Simcenter 3D software in a managed environment with Teamcenter software for integration. Discover the benefits of Simcenter 3D in combination with the power of Teamcenter for the storage and retrieval of data in a controlled fashion.

OptiAssist for Simcenter 3D

An add-on module, OptiAssist helps you develop optimal ply shapes and laminates for composites. When working with castings and moldings, it optimizes workflows to automatically develop material thickness distribution requirements.

A Common UI for Easier Training and Collaboration

Simcenter 3D provides some features to help you get ahead of the labor shortage, starting with a scalable environment for design engineers, analysts, and discipline specialists.

This centralized environment has a common user interface (UI) that’s shared across all Siemens CAE solutions. This offers benefits including:

- Reduces training costs across multiple, solver-specific tools

- Makes cross-training of engineering staff easier

- Facilitates shifting resources to the most pressing projects

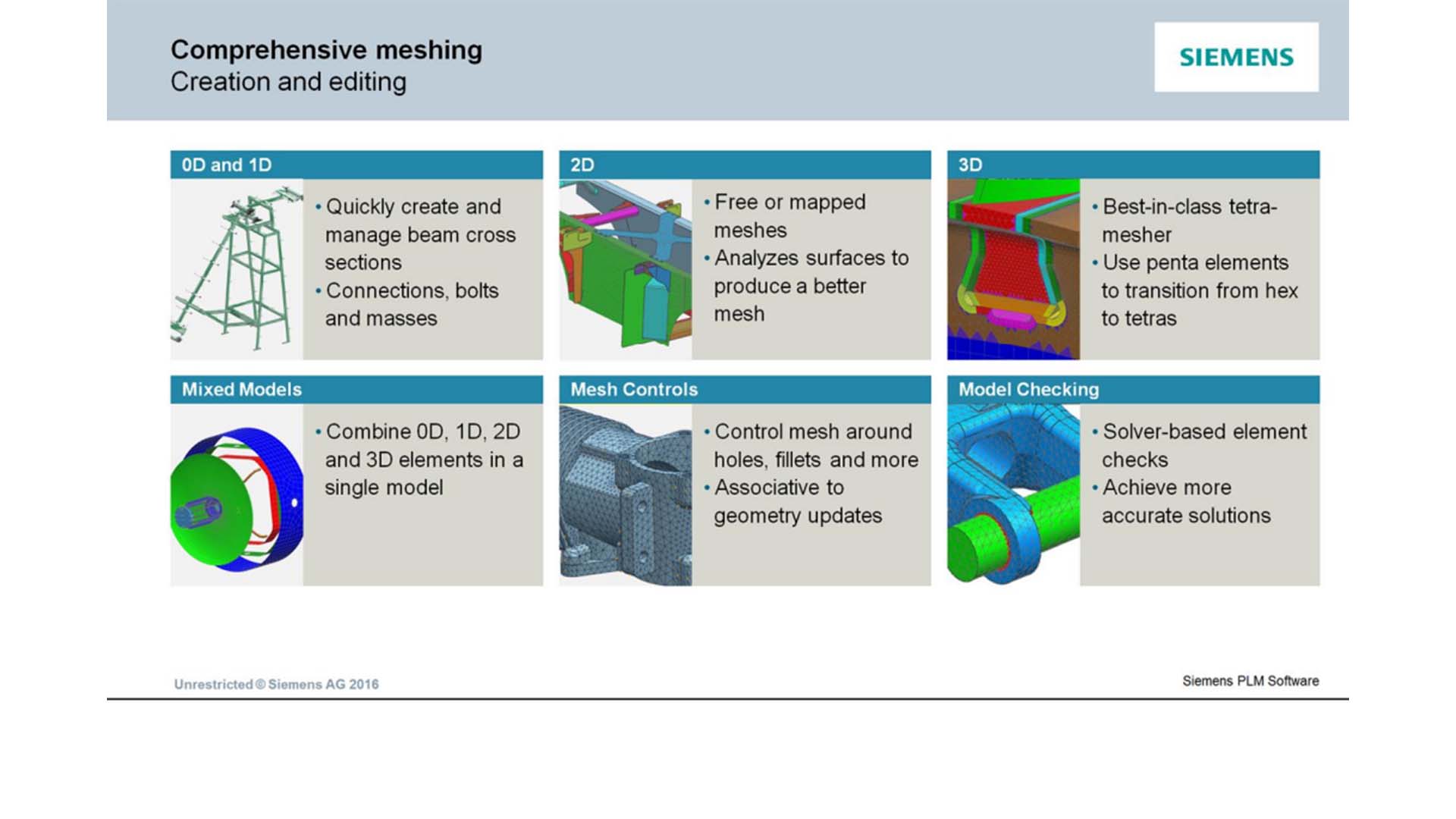

Superior Meshing for Easier Modeling

Dramatically cut modelling time and recoup time that would otherwise be lost with each design-analysis iteration. Simcenter 3D accomplishes this through powerful modeling with both automatic and manual mesh generation of 0D, 1D, 2D, and 3D elements, along with techniques to apply loads and boundary conditions.

Unlike competing solutions, Simcenter 3D associates the analysis model to its geometry. This means that changing geometry, mesh, and boundary conditions are all tied to the base design, so when you change the design geometry, the solution rapidly updates all existing analysis geometry, mesh, loads and boundary conditions.

Multiphysics Simulation and Designing for Safety

Benefit from new possibilities for vehicle safety and crash-test performance with Simcenter 3D. The solution offers an array of possibilities for model-based simulation and virtual testing. The solution’s multiphysics analytics cover:

- Multibody dynamics

- Finite element analysis

- Airbag computational fluid dynamics (CFD)

- Seatbelts, crash test dummies, and human body models

- Vehicle safety output

Open, unified, and extensible

Built-In Industry Experience

Years of industry experience are baked into the solutions found in Simcenter 3D. This includes some specific vertical solutions that incorporate lessons learned from clients’ use cases.

Choose from some specific vertical solutions such as:

- Electronic systems cooling

- Wind turbine applications

- Flexible pipes

- Tire modeling

- Modeling for noise, vibration, and harshness (NVH) in automotive

- Space systems thermal

- Aerospace applications including aerostructures and rotors

Improve Thermal-Flow Analysis

Do your designs involve the behaviors of fluids and heat exchange? Gain a thorough understanding of a design’s thermal-fluid characteristics to enable the precise tailoring of thermal management solutions.

This includes conduction, convection, compressible and incompressible fluids, radiation, phase change, two-phase, conjugate heat transfer, and the behavior of non-Newtonian fluids such as molten polymers.

Strengthen Your Team with a Digital Twin

Raise the visibility of your simulation team with a digital twin. Simcenter 3D provides a digital twin that delivers product performance information to decision makers when it makes a difference – early in the design cycle.

Decrease the constraints on innovation, break down silos between functional areas and help your design team become more flexible with Simcenter 3D coupled with Maya HTT’s expertise.

Unlock the full potential of engineering simulation with Siemens Simcenter 3D’s free trial!

Experience the power of advanced CAE software and embrace virtual prototyping for your product design. Dive into the world of multi-physics simulation, utilizing Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to optimize performance. Plus, delve into cutting-edge NVH analysis to ensure flawless product functionality. Sign up now to explore Simcenter 3D’s industry-leading simulation tools and accelerate innovation like never before.

Success stories

Building a competitive edge with building envelope simulation

Veridis is a simulation lab specialized in heat transfer and the energy efficiency of buildings....

Sub-Zero: Efficient design exploration for elegant refrigeration

Sub-Zero transforms utilitarian cold storage into top-of-the-line energy-efficient performance and...

Creating a Revolution in Farming with the Help of Simulation Software and Expertise

GreenForges designs and develops sustainable farming technology to move agricultural production...

Simulation

Simulation