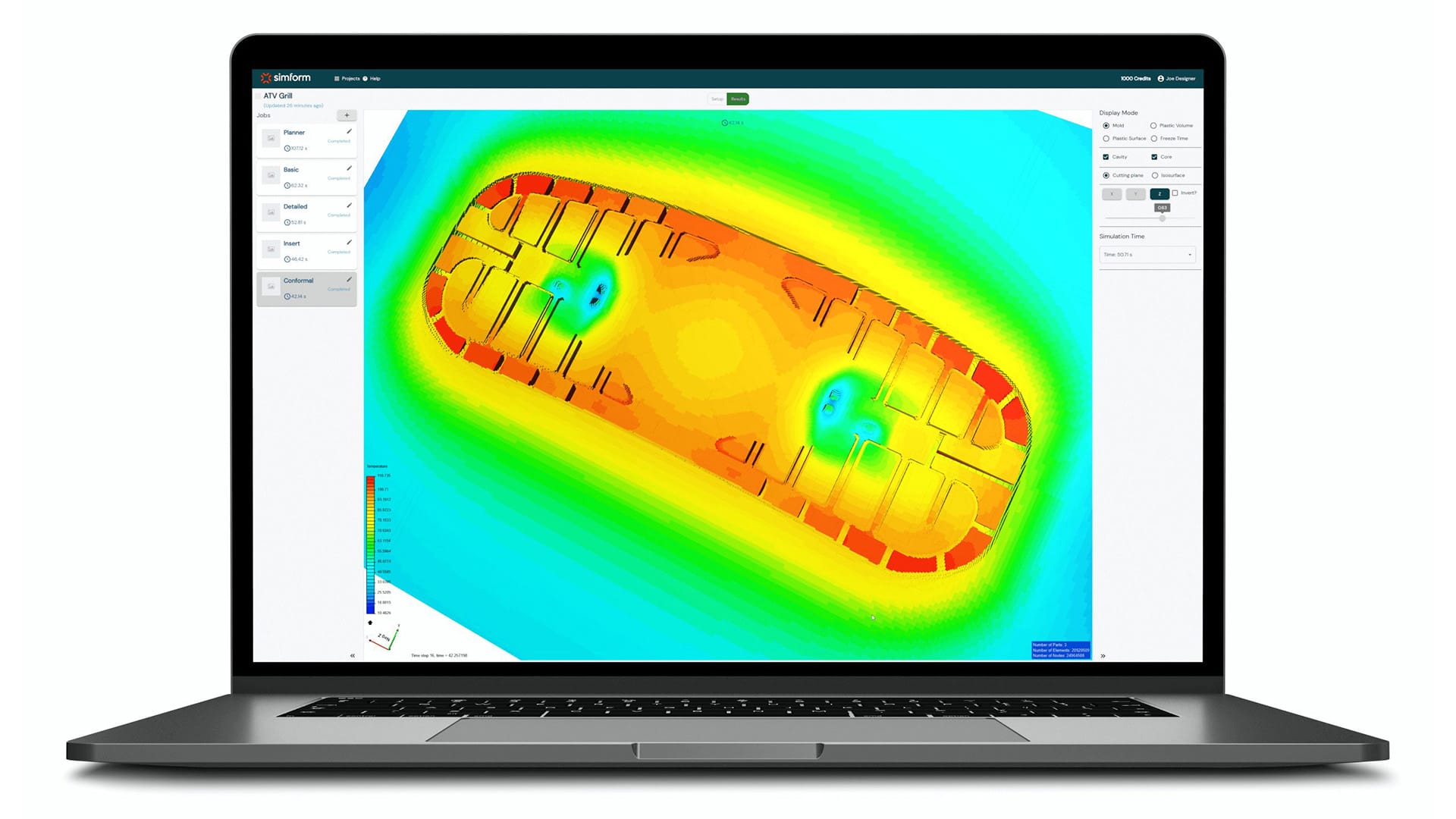

SimForm Mold Cooling.

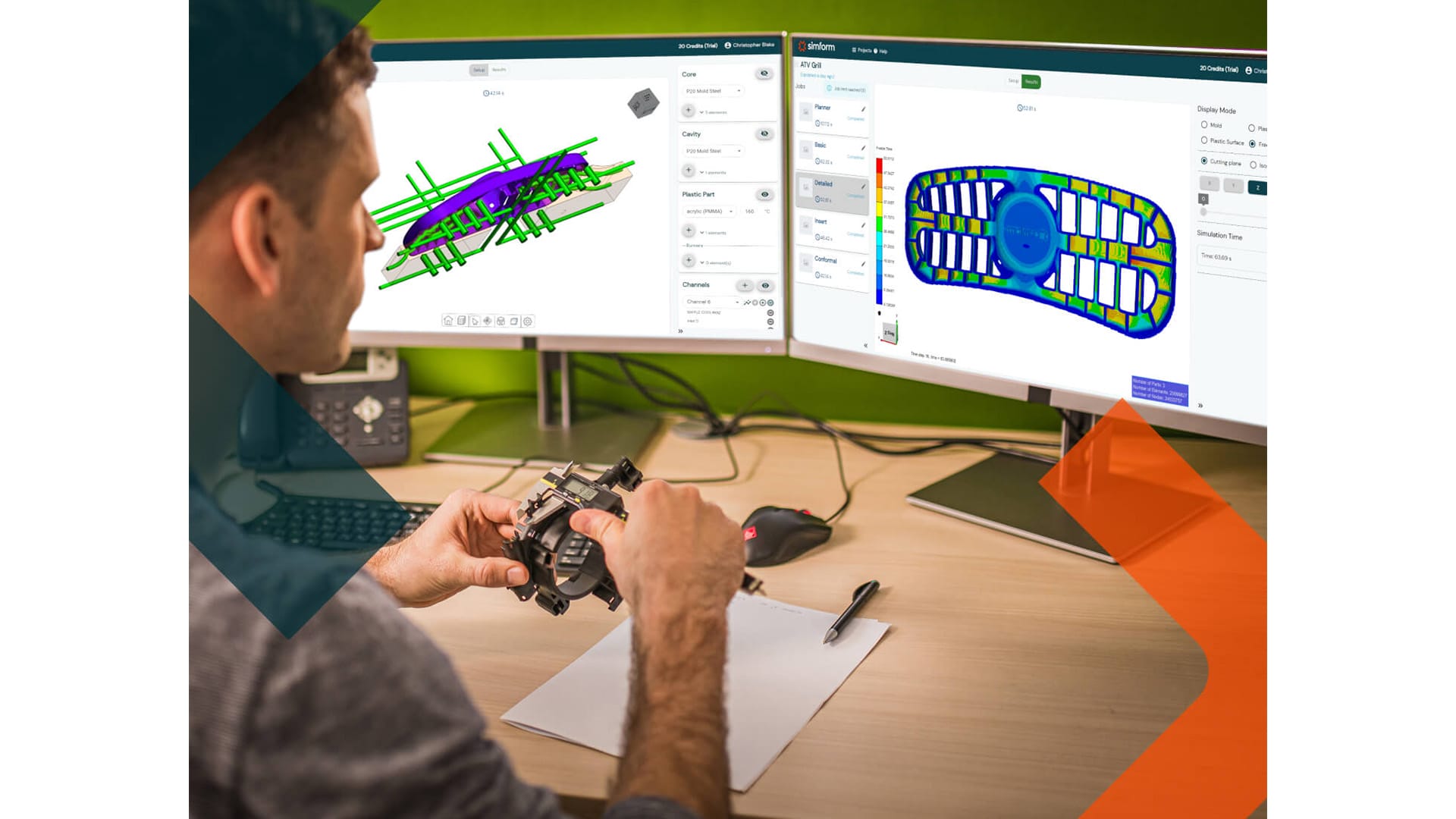

Front-end mold simulation software for mold designers and tooling managers

Mold designers

Immediately visualize temperatures with early hands-on simulation and plastic mold design software

Make the best mold design decisions

Back up decisions with visuals and data to support your mold designs. Injection mold design software for:

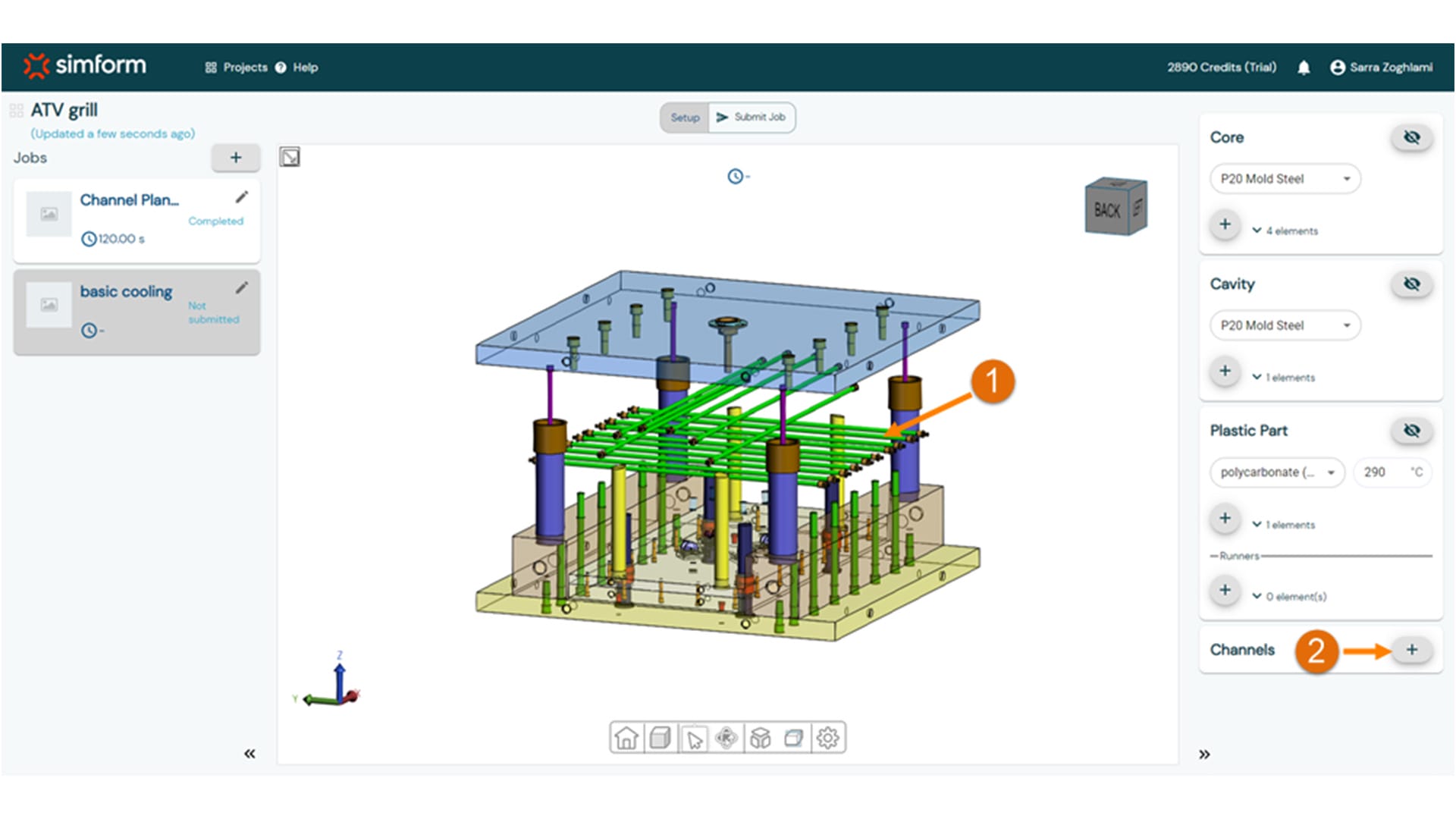

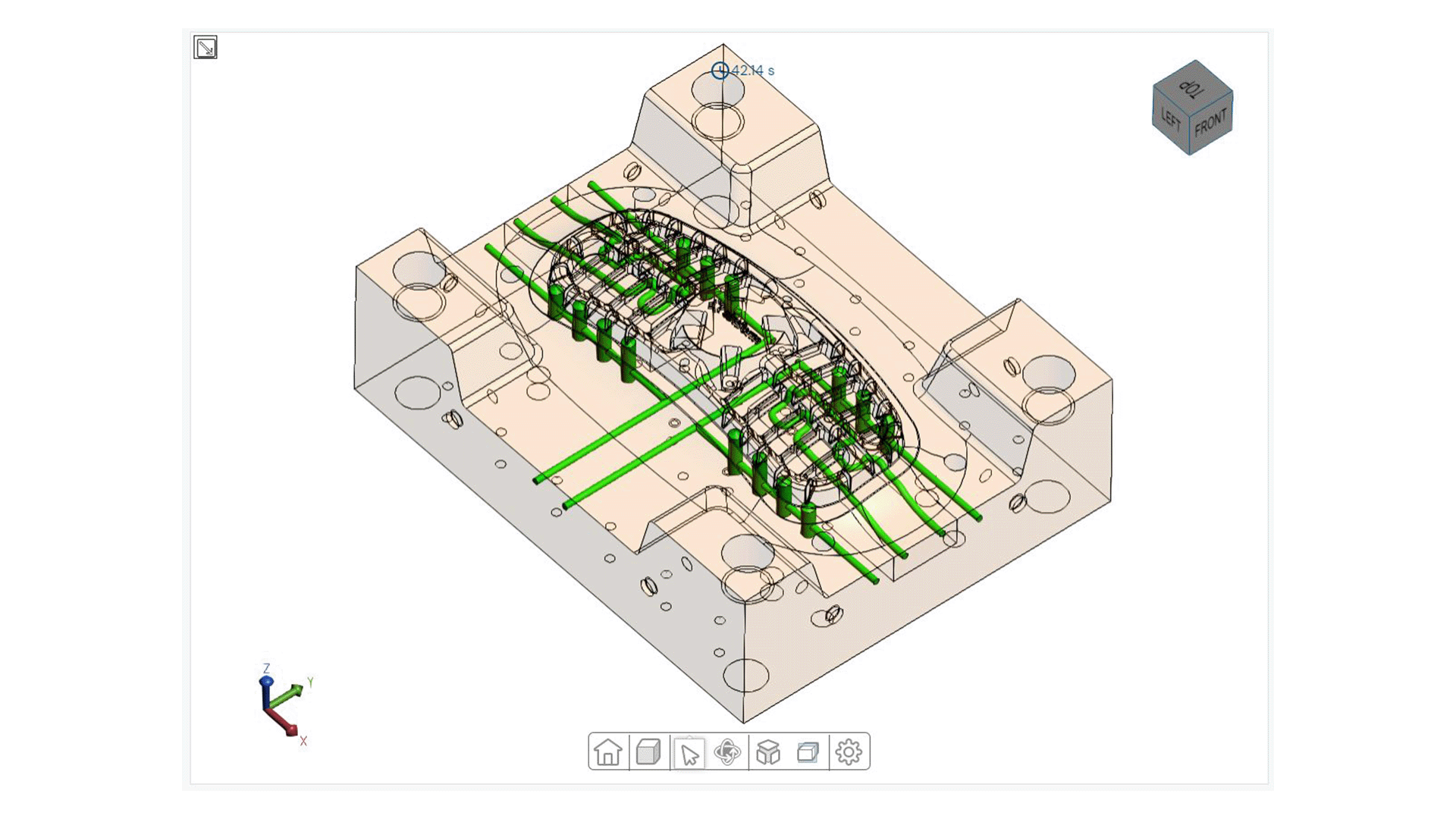

- Easy evaluation of the mold concept, water line locations, insert materials, conformal cooling, etc.

- Results that improve the location of mechanisms in the mold

Keep the design process flowing

Iterate faster and easily evaluate different options. Mold simulation software gives you:

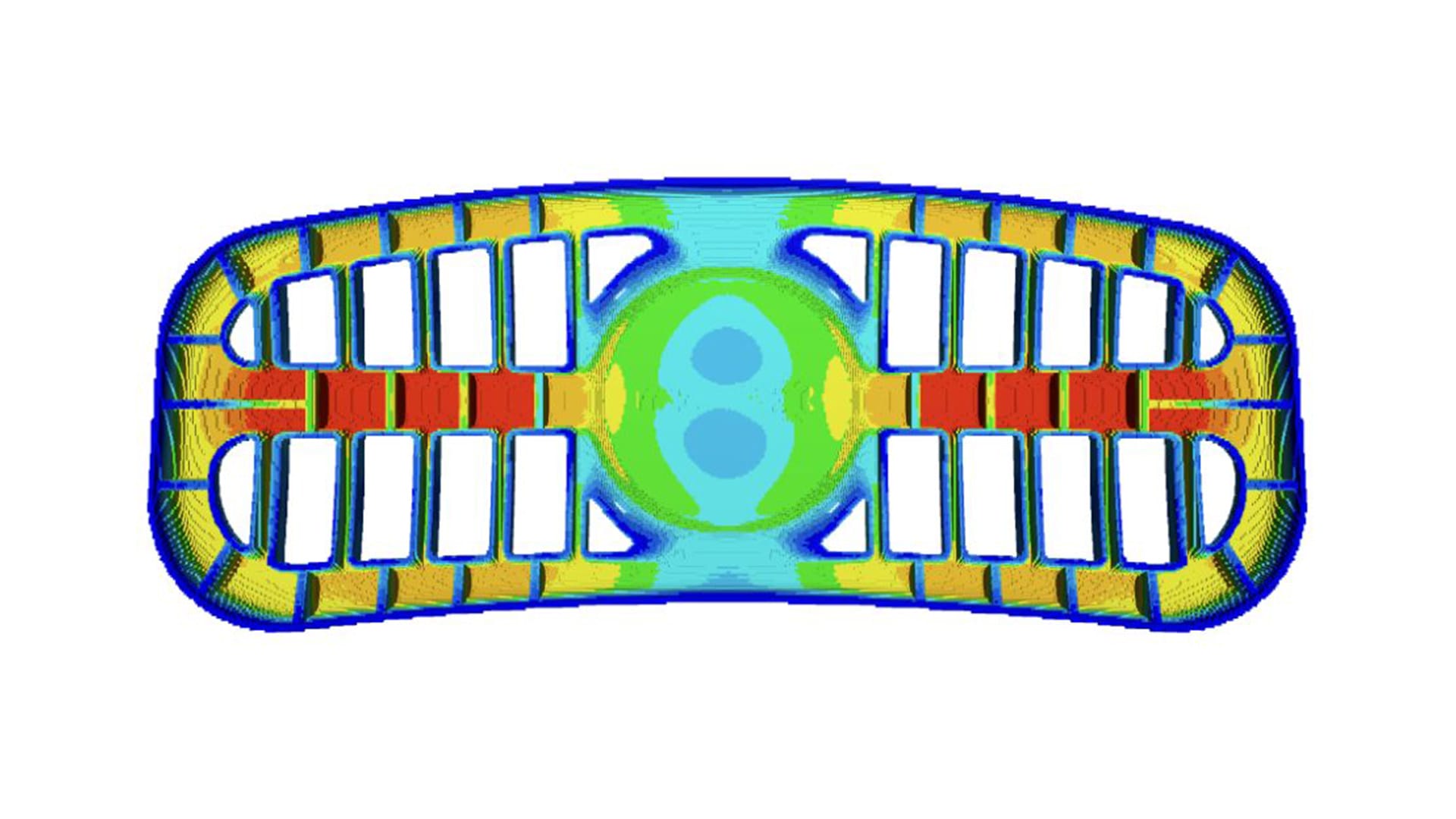

- Results in minutes, with only a few clicks: hot spots, temperature uniformity, and cooling time

- First-hand information, instantly, ahead of the simulation team

Have more ownership and see better results

Take charge of your mold design process with mold design software:

- “What-if” scenarios and business cases around the impact of part and mold design changes

- At-a-glance mold temperature visualization

Tooling managers

Make better business decisions and exceed client expectations with mold design software

Deliver client satisfaction

Become the first choice of molders with quality and confidence.

- Reduced design iterations for cheaper and faster mold development that your customers will appreciate

- Justification for design changes such as the addition of inserts or conformal cooling channels

Boost design teams

Ensure smooth processes for less friction and more team engagement

- Reduced design effort with less need for redesigns

- An exciting design environment for experts and new hires

Reduce the risk of rework

Break free from expensive errors, delays and stalled processes.

- Accelerated design cycles with less risk

- Less need for full mold flow simulation services

SimForm how-to and resources

Learn more about how to use SimForm in your mold design process

Simulation

Simulation