MAL NPRO.

Model, simulate, and understand machine processes at a physics level. Gain significant reductions in cycle times and cut machining costs.

Optimize NC Control

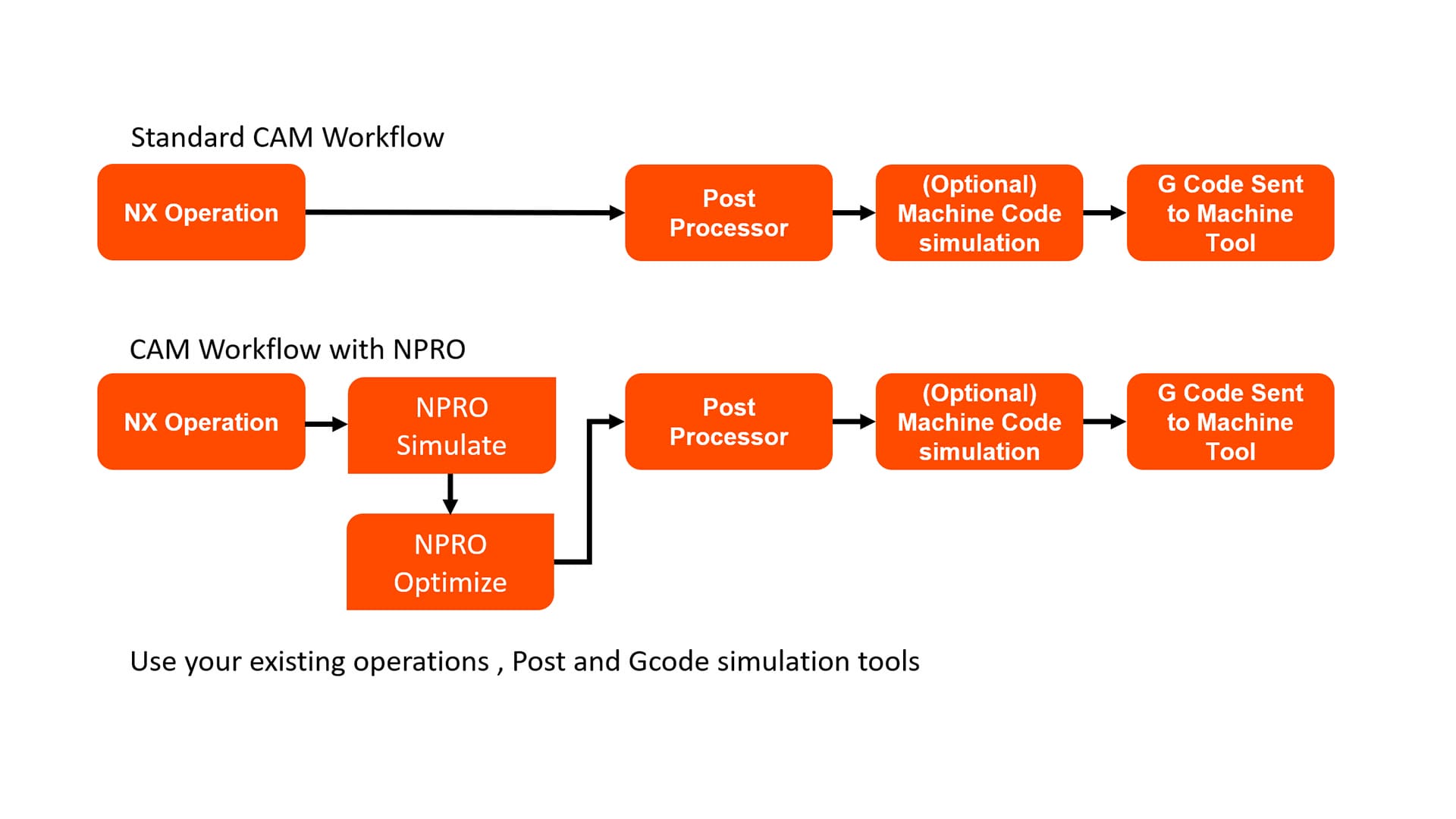

Unlike post-processing solutions, MAL NPRO works within NX to allow manufacturing planners to visualize, simulate, and optimize numerical control (NC) tool paths. By understanding the physics of the machining process, you can optimize feed rates and boost your computer aided manufacturing (CAM) program up to the physical limits of a machine and tools.

The only requirements are having data on the spindle graph and max feed rate, along with chip thickness from the manufacturer of the cutting tool you are using. Applications for NPRO include:

Any Milling Operation

- 2.5 axis

- 3.0 axis

- 5 axis machining

Any Turning Operation

- OD turning

- Boring

Charting a Better Toolpath

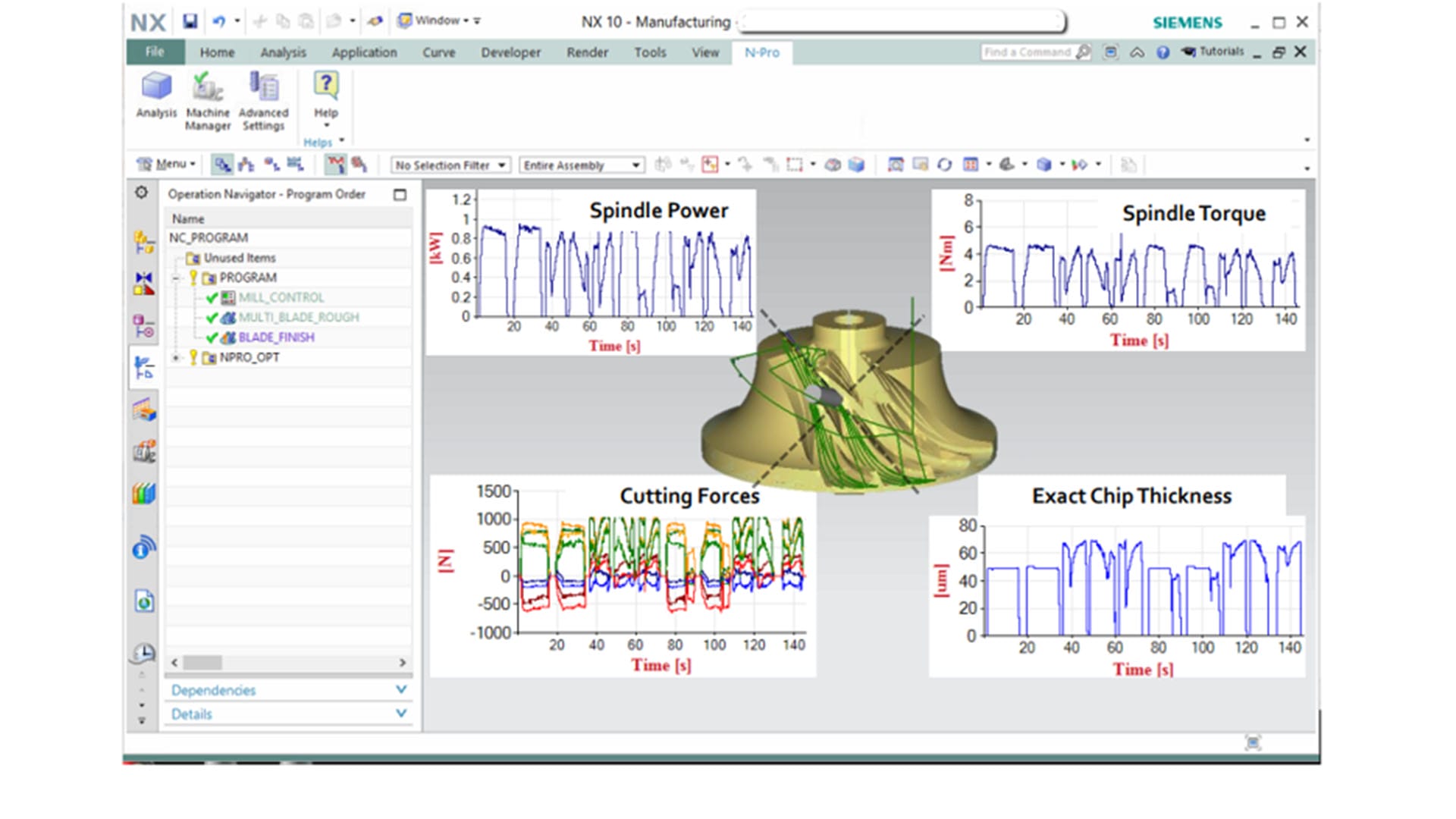

NPRO’s process simulation extends to visualizing and planning computer numerical control (CNC) toolpaths to optimize the toolpath for a given operation.

Toolpath optimization features include modeling:

- Spindle torque/power

- Cutting load

- Chip thickness

- Tool bending forces

NPRO Demonstration

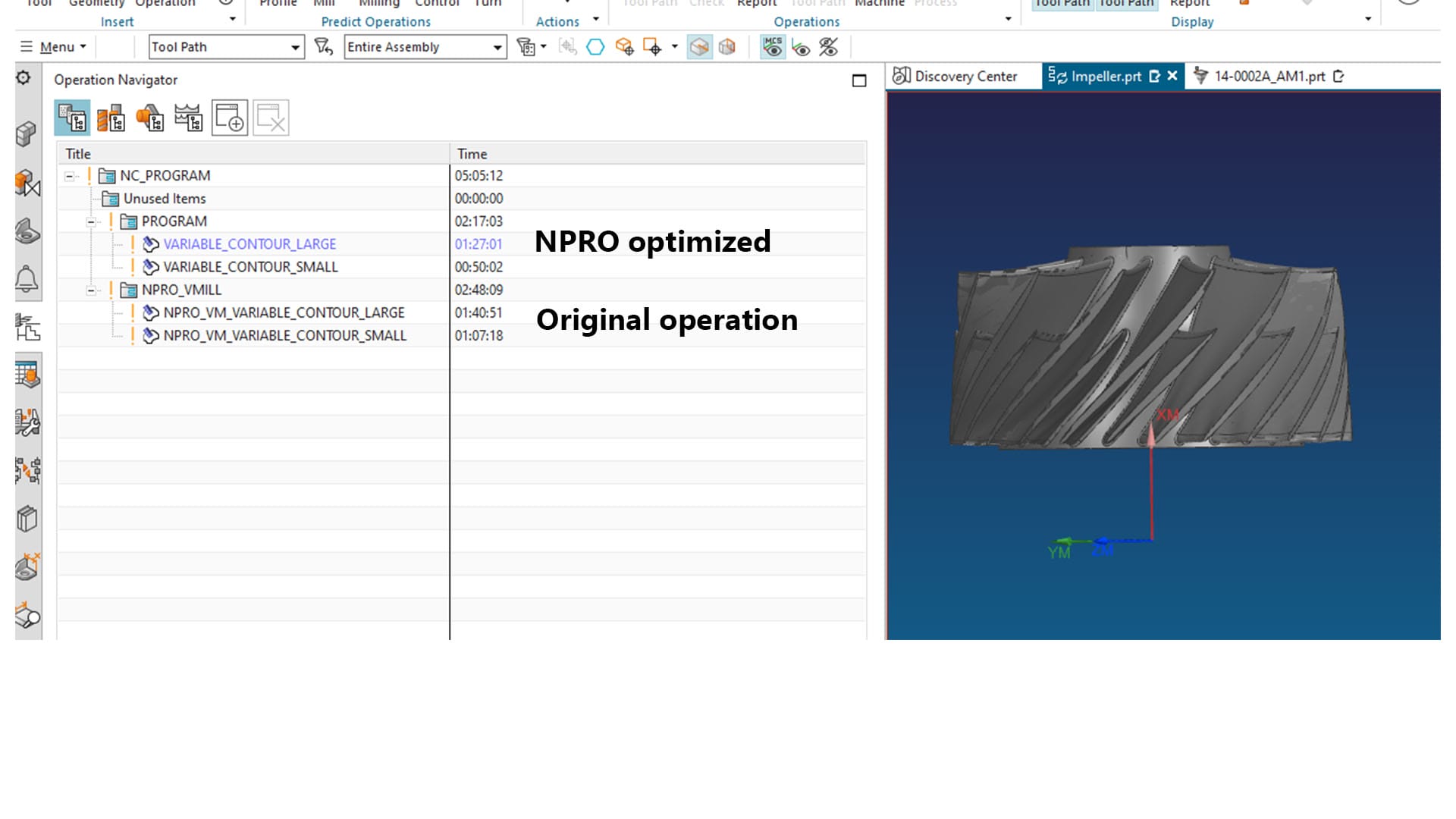

Reduce Machining Costs

Reduce your cycle times and increase production rates using your current equipment with NPRO program optimization. Having access to spindle power, torque, and tool bending force can also play an important part in selecting optimal consumables.

Process planners tend to use larger, more expensive tooling then required. Stop using more expensive consumables to increase perceived process stability because the process is not understood. NPRO arms you with the data you need to do this. You can also leverage this data to make optimal spindle selection decisions when purchasing new machines.

An Easy-to-Use Optimization Tool

With its intuitive interface and integration with NX, NPRO is quick to learn and easy to use. There are basically just three steps, and you perform them directly inside NX:

- Select the desired operations

- Simulate the operations to gain an understanding of the cutting mechanics

- Create optimized operations using the simulate results as a guide

Due to NPRO’s integration at the operational level, users continue to use the same tools they are already familiar with.