Simcenter SPEED.

Get a fast and comprehensive solution for designing electric machines. Simcenter SPEED’s theoretical and physical models and system-level simulations support optimal design workflows.

Design Any Type of E-Machine, Quickly

A rapid machine design tool, Simcenter SPEED uses equivalent circuit analysis to deliver much faster results. Use it to design:

- Synchronous machines including permanent magnet, reluctance, and wound field rotors

- Switched reluctance machines

- Induction machines

- Axial flux machines

- Brushed DC machines

- Wound-field commutator machines

Templates for Input and Output

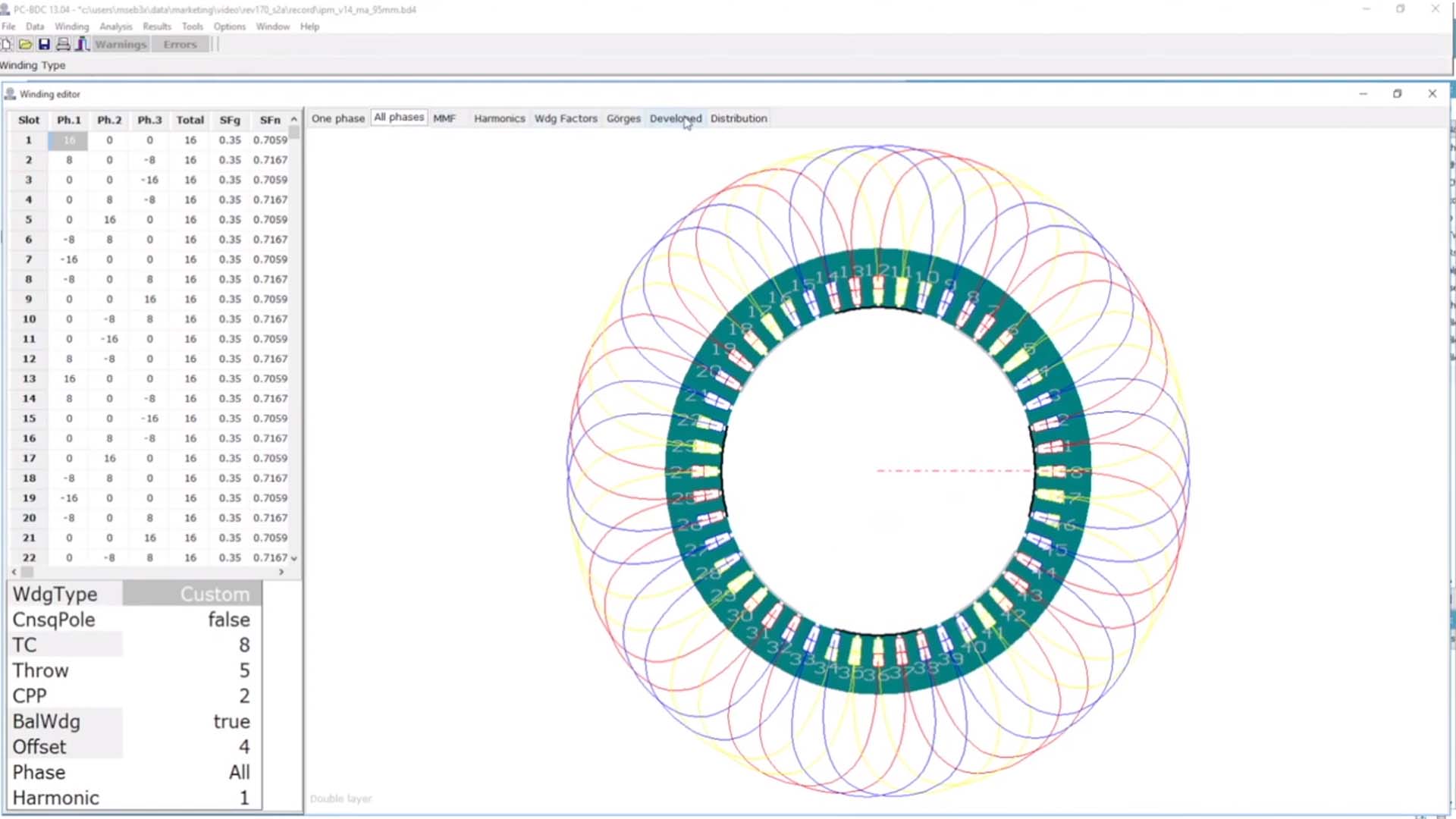

Benefit from quick and intelligent usage of 2D finite element (FE) magnetostatic analysis for more precise modeling of magnetic saturated regions. Collect input parameters with Simcenter SPEED’s template editor, which provides easy setup and access to a wide array of parameters such as motor geometry, winding details, and more. There are also common databases with material properties, charts, and plots.

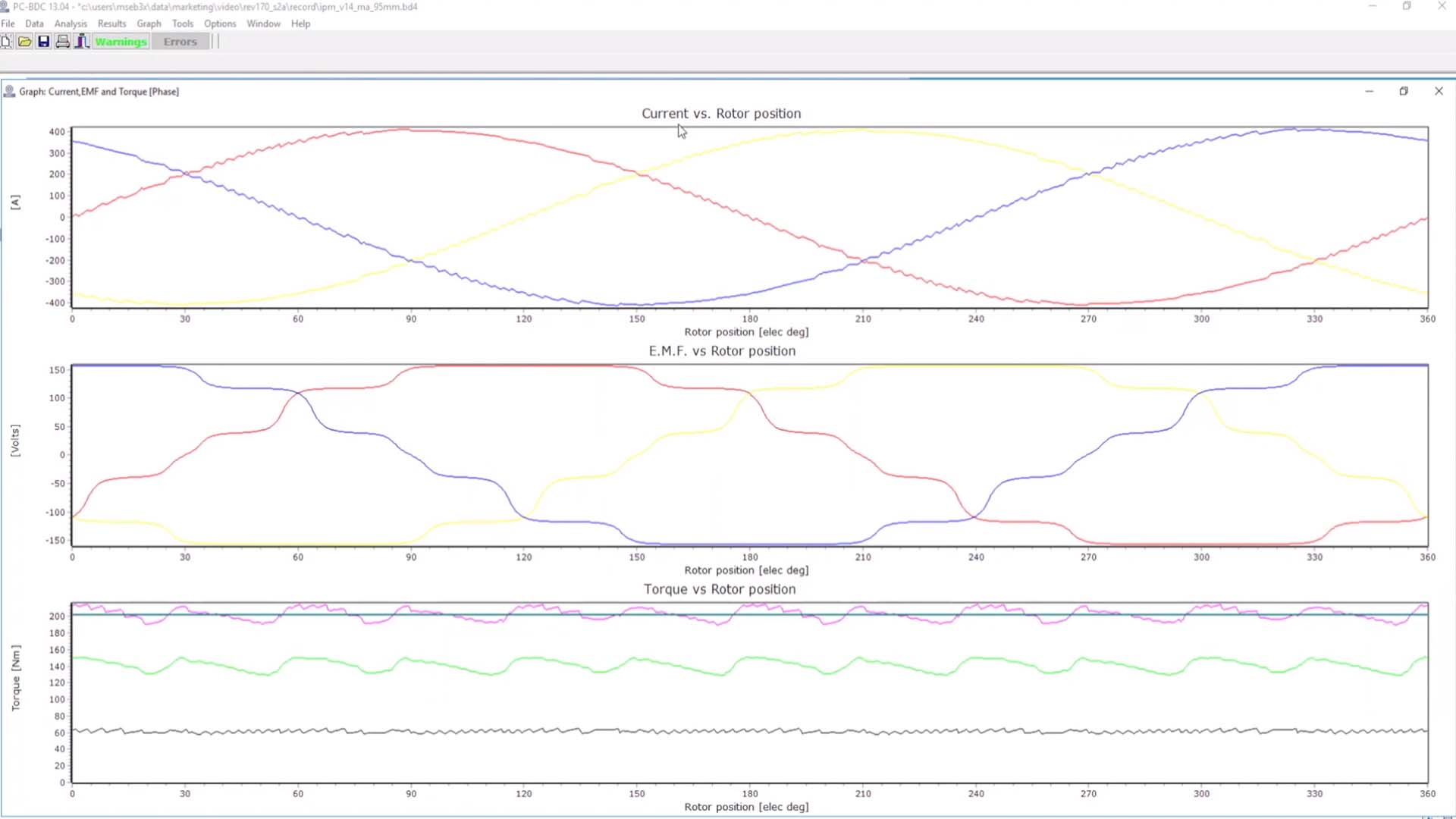

The solution’s design sheet outputs numerical data and creates output graphs to visualize results including current, torque, back EMF, and efficiency mapping for quicker analysis.

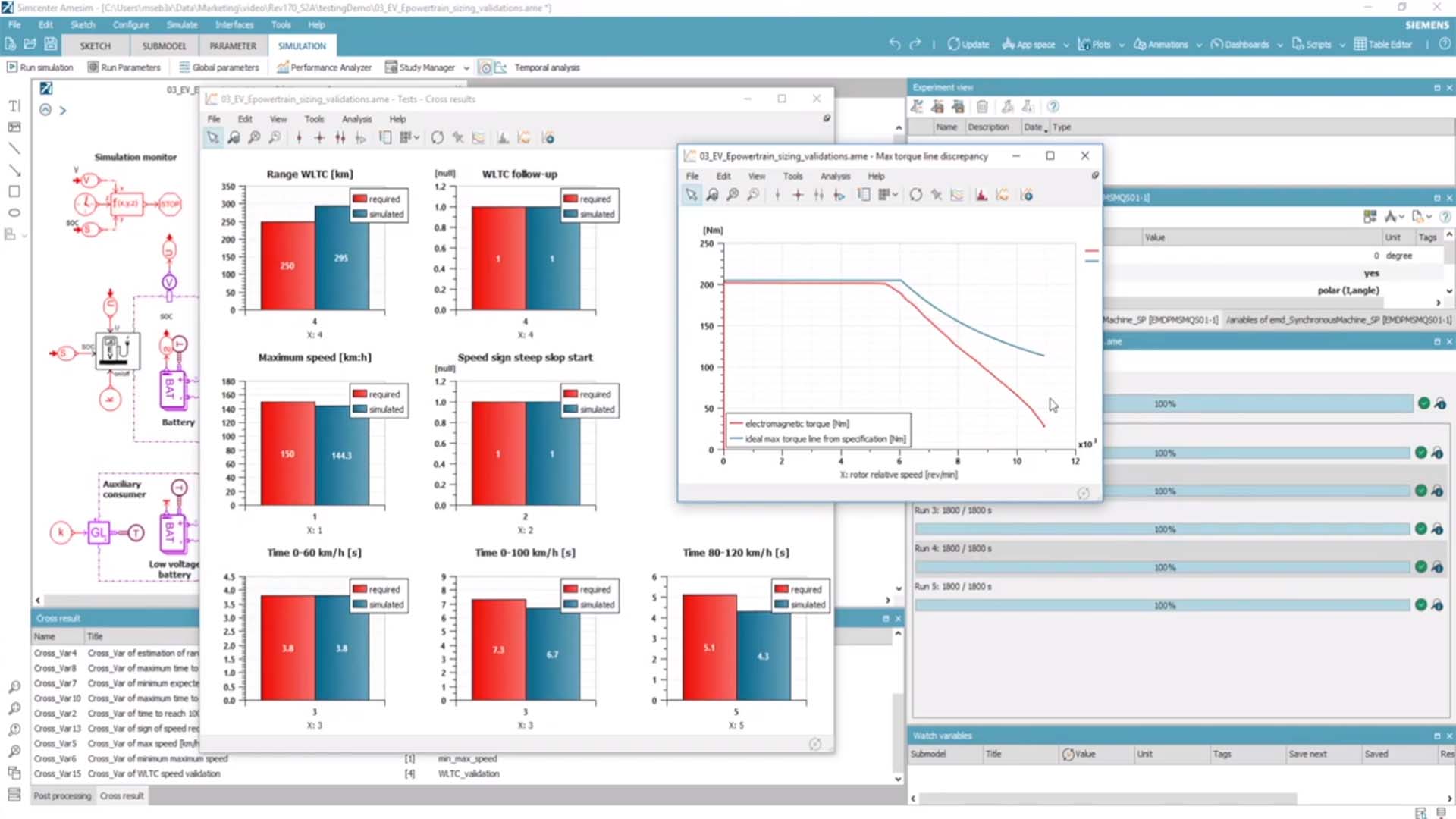

Simulations at the System Level

The design of an electric machine must often take into account that it may be part of a complex system whose overall design must also be considered. You can benefit from Simcenter SPEED’s predefined parameters and system mapping to fully “place” a machine in context.

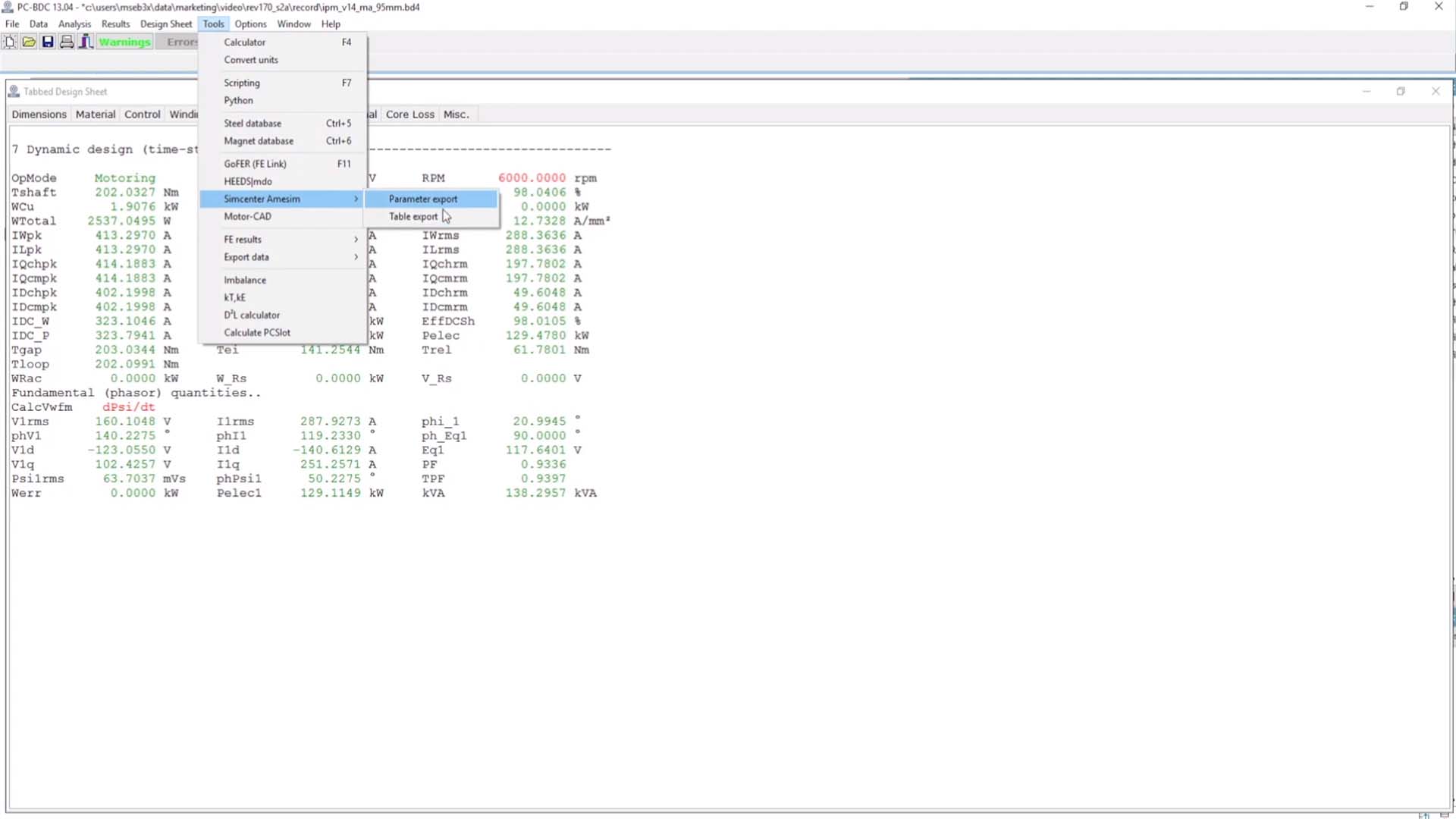

Simulation files from Simcenter SPEED are inherently compatible with Simcenter Amesim, allowing “one click” importing of files. Integrating both solutions allows you to:

- Export a list of linear parameters

- Create 2D maps showing flux linkage with iron loss

Designing for Special Conditions

Bring more speed and efficiency to your design process even in special circumstances.

Simcenter SPEED connects to a dedicated 2D magnetostatic program – Simcenter SPEED FEA Solver. This embedded solver enables precise analyses for special cases such as high saturation or fault conditions. Using the simulation results, SPEED’s equivalent circuit model can be accurately calibrated to return results that more closely match the physical world.

Software Linking for Design Exploration

Innovation is easier when engineers are free to explore the design space, run “what if?” scenarios, and even automate the design exploration process.

Simcenter SPEED’s connectivity tools enable you to readily integrate it with other solutions to further expand its capabilities.

Link Simcenter SPEED with Simcenter STAR-CCM+, Simcenter MAGNET, or Simcenter 3D to enable scripting automation and analysis using the multiphysics solvers for electromagnetic, mechanical, and thermal analses. Simcenter SPEED also connects with HEEDS, which adds powerful automation capabilities to the entire process of design exploration.

Success stories

Building a competitive edge with building envelope simulation

Veridis is a simulation lab specialized in heat transfer and the energy efficiency of buildings....

Sub-Zero: Efficient design exploration for elegant refrigeration

Sub-Zero transforms utilitarian cold storage into top-of-the-line energy-efficient performance and...

Creating a Revolution in Farming with the Help of Simulation Software and Expertise

GreenForges designs and develops sustainable farming technology to move agricultural production...