Quick Overview

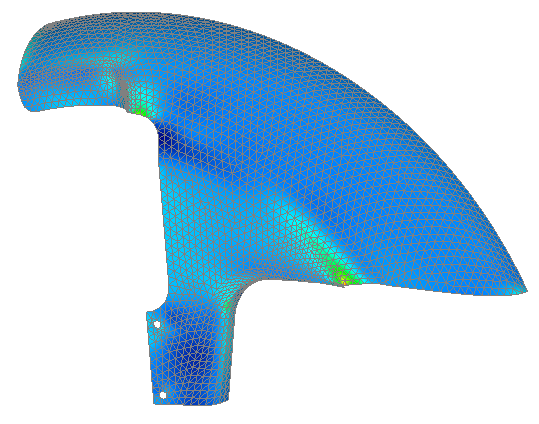

This post-processing Tip & Trick will show how to efficiently use predefined Femap API and a customized toolbar for laminates. This example, created in Femap 11.22, shows a 2D laminate mudguard model. Figure 1 & Figure 2 are showing ply failure indices for ply 1 and ply 2 respectively.

Figure 1

Figure 2

Steps

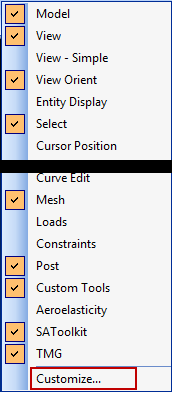

The first step is to create new user commands and tie them to a user toolbar. Using the mouse, right-click next to already existing toolbars. The menu (Figure 3) will be displayed. Then click on “Customize” (Figure 4) and switch to “User Commands” Tab

Figure 3

Figure 4

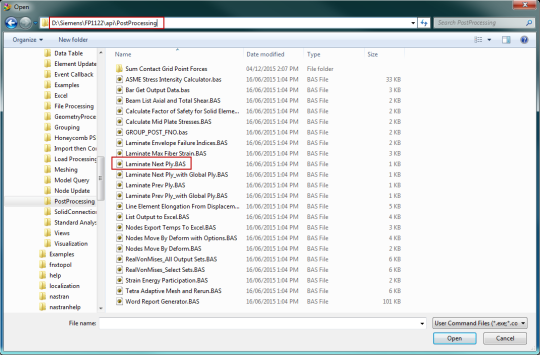

In the field “Command Name” [1], enter a descriptive value like “Next Ply”. For the Program [2], hit the browser button and go the your Femap installation folder and then APIPostProcessing (“Femap Root”APIPostProcessing) and select the file called Laminate Next Ply.BAS and hit Open (Figure 5).

Figure 5

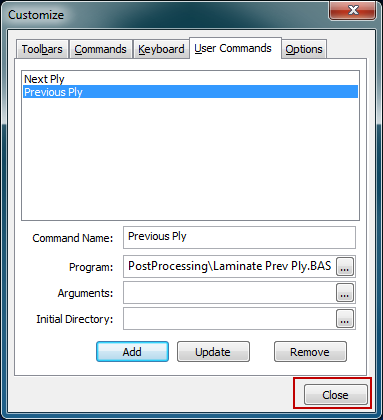

You will be back on the “User commands” menu (Figure 4), then hit “Add” [3] and you will end up with a new user command like Figure 6

Figure 6

Repeat the previous steps with “Previous Ply” for the Command name and the file to be selected is Laminate Prev Ply.BAS. You will end up a second user command. Then close the menu. (Figure 7)

Figure 7

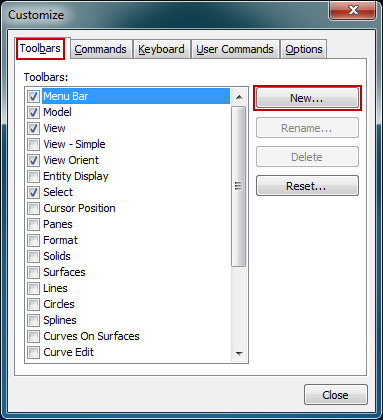

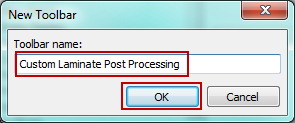

Reopen the menu from Figure 3 with a RMB on the toolbar area and create a new toolbar named Custom Laminate Post Processing. (Figure 8 & Figure 9)

Figure 8

Figure 9

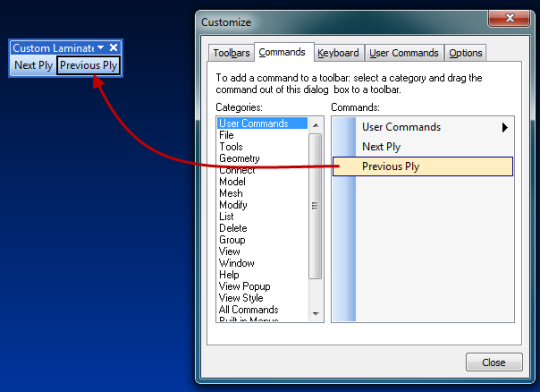

Once this is done, select the “Commands” tab and drag and drop the 2 new user commands into the previously created toolbar. (Figure 10)

Figure 10

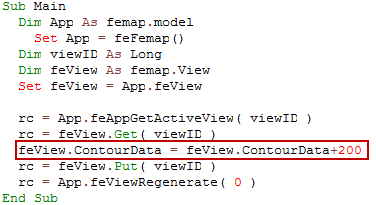

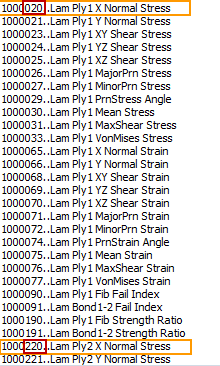

You are now ready to use the new commands. If you open the .BAS file that contains the API program, you will notice that the command does a step of ±200 in the vector ID for the post processing, effectively changing the ply ID with the same results. (Figure 11 & Figure 12)

Figure 11

Figure 12

The same could be done for Global Ply ID. Files are already present in the same directory. Note that it can also be used for a 3D laminate.